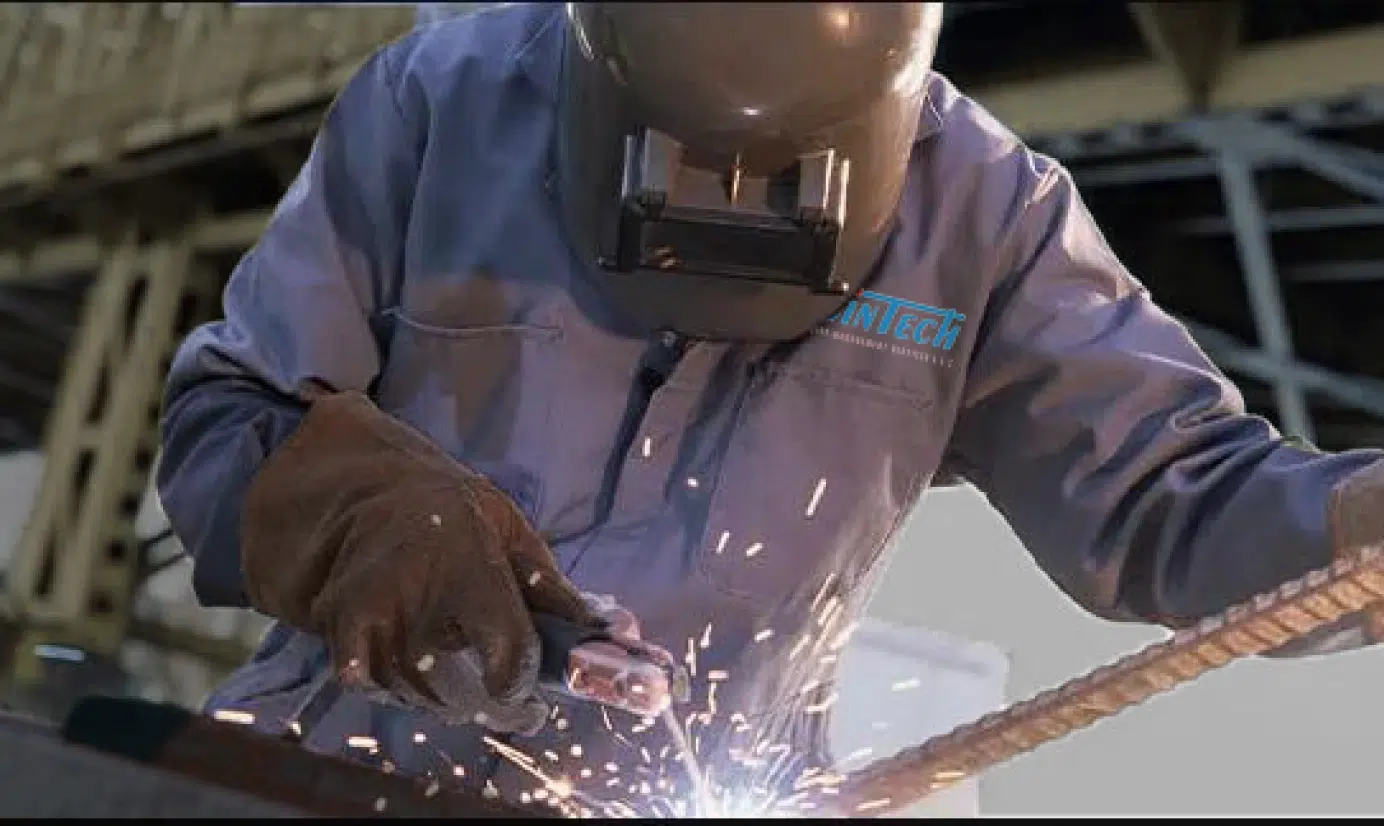

A welder is responsible for joining metal parts or repairing damage to components, using heavy machinery that emits large amounts of heat and melts the metals into shape. JoinTech, one of the premier provider of skilled welder manpower supplier in Abu Dhabi. Capable to create durable components using heavy machinery to shape the metals that endure extreme pressures and temperatures to support structural development. Welders operate with equipment to fuse metals using various cutting, gouging and welding processes on pipelines, rigs, plants and facilities. Our workforce are steady and physically strength to operate heavy pieces of metal according to the welding process specifications

- Plan to assemble components for welding according to specifications.

- Operating with angle grinders to prepare the parts and components are welded using manual or semi-automatic welding equipment in different positions.

- Repair machinery and other components by welding pieces and filling gaps.

- Test and inspect welded surfaces and structure to discover flaws.

- Operate manual or semi-automatic welding equipment to fuse metal segments using processes such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), plasma arc welding (PAW), shielded metal arc welding (SMAW), oxy acetylene welding (OAW), resistance welding and submerged arc welding (SAW).

- Functioning with manual or semi-automatic flame-cutting equipment.

- Operating with brazing, soldering equipment, metal shaping machines such as

- brakes, shears and other metal straightening and bending machines.

- Repair worn parts of metal products by welding on extra layers.

- Our welder perform multitasking on worksite including, working on pipeline systems, derrick and pump jack repair, installations, and closing off a producing well. Effectively communicate with others when collaborating on large-scale projects. In MEP industry, we supported to provide different types of welders performing variety of applications, including maintenance and repair, construction, industrial fabrication and more,

- SMAW

- Tig, Mig & Arc welder

- 6G welder

- Rig welder

- Assist in installation, layout and identify bonding points on subassemblies.

- Fabricate, install and repair sheet steel products & equipment.

- Perform basic welding positions by choosing the accurate electrode with professional speed and accuracy to get reliable results.

- Selecting right welding transfer modes.

- Perform horizontal, vertical and overhead welding operations.

- Align components using calipers, rulers and clamp pieces.

- Prepare and finish work piece using portable grinder, or scraper.

- Identify common weld defects and rectify them.

- Ability to measure metal parts using calipers, welding templates and straightedges accurately.

- Comparing material dimensions and performing quality control process by testing the strength of each intersections.

- Calculating dimensions based on the specifications and weld metal parts using brazing/ gas welding/ arc welding process.

- Manage inventories of welding equipment and materials.

- Analyzing defects/ outflow to identify the root cause and formulate with effective solution.

- Performed Tig welding of metals like iron, steel and copper and nonmetal like plastic and fiberglass.

- Determining correct gas ratios and perform maintenance/repair activities for piping systems.

- Assisted with Plumbers and HVAC workforce as required.

- Performing thermal cutting and grinding operations.

- Following proper welding procedures and instructions for routine maintenance or repair work.

- Determining the configuration and specification of a structure to produce high quality results.

- Implement technical methods to assemble or repair metal components by measuring, cutting, and joining appropriate metals.

- Capable to read machine instructions in order to set electrode polarity.

- Ensure connections are fixed appropriately within the range of flow rate.

- Shielding gas transmitted through the welding gun and protects the weld pool from contaminants.

- Subsequently monitoring the strength of welding process to avoid impurities and porosity.

- Welds and assembles metal components such as stainless steel and sheet metal.

- To identify potential welding problems and work out the solution.

- To assist Engineer in welding quality issues and improvement.

- Ensure assigned daily work schedule and production target is achieved.

- To comply with all applicable quality,health,safety and environmental regulations.

- Performs all kinds of welding, brazing and cutting on any type or metal using tools commonly used in welding work. Works in accordance with Hablem practices and specifications and the ASME Code (QW-405-6-G Fixed) for Welder certification.

- Plans layouts,constructs,installs,repairs and maintains all types of pipelines,fittings and fixtures as required in plant construction and maintenance using tools commonly used in pipefitting work.

- Work closely and interacts with supervision and QA/QC.

- Reads and understands P & ID drawings and other package layout drawings to determine appropriate welding process.

- Weld metal materials to piping systems equipment using the appropriate welding procedure for the various equipment and metal types involved.

- Possess high knowledge and understanding of company products and services.

- To provide daily report or current updates in Engineering Department and other related Whatsapp group for good news, issues, tasks and plans.

- To carry out such other duties & responsibilities as per Company required from time to time.

- Welds and assembles of RO Plants.

- To identify potential welding problems and work out the solution.

- Keep Engineer updated on work progress.

- To assist Engineer in welding quality issues and improvement.

- Ensure assigned daily work schedule and production target is achieved.

- To comply with all applicable quality, health, safety and environmental regulations.

- Performs all kinds of welding, brazing and cutting on any type or metal usingtools commonly used in welding work.

- Plans layouts, constructs, installs, repairs and maintains all types of pipelines, fittings and fixtures as required in RO plant.

- Work closely and interacts with supervision and QA/QC.

- Reads and understands P & ID drawings and other package layout drawings to determine appropriate welding process.

- Weld metal materials to piping systems equipment using the appropriate welding procedure for the various equipment and metal types involved.

- To carry out such other duties & responsibilities as per Company required from